Get every single important Permit and Authorisation required for your Pulse Milling Industry with master help from Enviroxperts.

Package Inclusions :-

Outline of the Pulse Milling Industry

India is figured as the biggest maker of pulses in the world. Significant heartbeats developed are chickpeas (gram), Masur (lentil), pigeon peas (tur or arhar), moong beans, urad (dark matpe), peas and different sorts of beans. Beats are 20 to 25 percent protein by weight, twofold the protein focus in wheat and triple that of rice. Beats are consumed in their de-husked and split structure, ordinarily termeddal. Beat processing (also known as dal processing) is achieved in three significant stages: releasing husk, de-husking and dividing beats. Besides, the cycle is completed in the beat processing industry, India’s third biggest food handling business after rice and wheat.

Customary techniques for handling beats were work escalated, tedious and caused misfortunes. Present day advancements being utilized in the beat processing industry have supplanted advanced age techniques. Hence, this has helped in staying away from misfortunes and saving time. Industriescarry out beat processing by performing essential unit activities like cleaning, evaluating, drying, relaxing husk, de-husking, parting and cleaning. Despite the fact that the essential processing methodology is like automated processing, the particulars of de-husking strategies fluctuate generally starting with one dal plant then onto the next and from one area to another.

This business is being set up in the limited scale industry in many heartbeat creating region of the country. Setting up a heartbeat processing industry is moderately simple and doesn’t require high capital ventures. These benefits related with the business permit ranchers to participate in esteem expansion and give them more benefits.

Handling stages did in Pulse Milling Industry

To set up a pulse milling industry, a business person should be know all about the predominant practices. S/he ought to likewise have major areas of strength for an of hardware utilized in processing different dal/beats. The handling stages in beat processing are –

Cleaning and Grading:Beats got at the plant should be cleaned and size evaluated for yielding great quality dal with higher recuperation. In any event, during the de-husking activity, beats are exposed to sieving to isolate husk, broken, parts, gota (de-husked pulse) and entire (unhusked) beats.

Drying:This stage is important to guarantee the protected stockpiling of pulses prior to completing the activity. This is important as pulses got in the beat processing industry by and large have higher dampness content. After the soaking of pulses to release the husk, drying them is likewise vital.

Loosening of Husk:This is a crucial step in pulse milling as it decides the total recovery and quality of the milled pulses.

Dehusking:Roller de-huskers coated with carborundum are used to de-husk the pulses.

Splitting:Splitting operation involves loosening the bond between the cotyledons and splitting it.

Machinery Required in Pulse Milling Industry

The following machines are required in the Pulse Milling Industry –

Destoner cum Grader cum Aspirator – It removes stones, sticks, dust particles and other unwanted impurities from the threshed produce.

Dal Oil Mixer – Before de-husking, an appropriate quantity of oil blending with the cleaned pulses is required to soften the hard coat.

Pulse/Dal Dehusker – An indispensable part of the pulse milling industry, it removes the hard coat of black gram, green gram and red gram.

Grader cum Aspirator – It removes the lightly attached skin and is left after de-husking.

Dal Splitter cum Grader – It is used for splitting the dal into two halves and then subsequent grading.

Licenses and authorisation required for Pulse Milling Industry

FSSAI Permit

FSSAI Enlistment offers a 14-digit permit number imprinted on all food things. Acquiring this permit gives the beat processing industry lawful advantages and assembles generosity. The enrollment additionally guarantees sanitation, makes shopper mindfulness, and helps the business visionary in business expansion.FSSAI permit number subtleties the collecting state, maker’s grant and so on.

A Central FSSAI Permit is expected for the beat processing industry, where the turnover is in excess of 20 crores. A State FSSAI Permit is required on account of medium food organizations where the turnover is between 12 lakh to 20 crore. A fundamental FSSAI Enrollment is expected on account of a trivial food business where the turnover is under 12 lakh.

If we consider the case of state FSSAI licence, the documents required by a pulse milling industry in this regard are –

- Duly filled out Form B

- Layout plan of the unit with dimensions in metres/square metres and operation-wise area allocation

- List of directors

- Name and list of equipment

- Photo ID

- List of food categories desired to be manufactured

- Test analysis report

- Land ownership documents

- Copy of certificate obtained under Coop Act

- NOC and copy of the licence from the manufacturer

Consent No Objection Certificate (NOC)

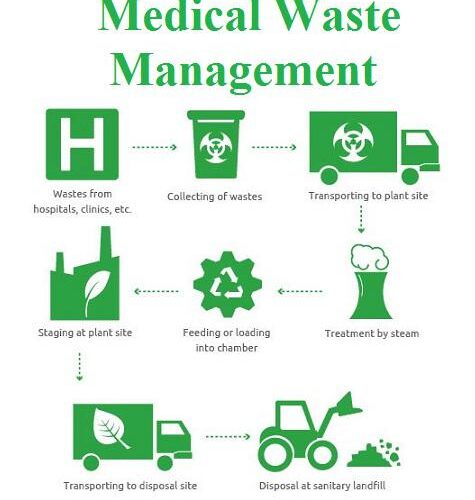

An assent testament is given by the concerned State Pollution Control Board (SPCB)/ Pollution Control Committee(PCC) to modern foundations like the beat processing industry. This declaration is given before the units start their activity. The assent NOC is given in two phases: Consent to Establish (CTE) and Consent to Operate (CTO).

Documents required for Consent Certificates

- Duly filled application form

- Signed undertaking in the prescribed format

- Site or layout plan, along with a roadmap

- Detailed project report and total project investment

- Details of products, manufacturing process, list of machinery, capital, water balance and source and required quantity

- Land ownership proof, like lease/rent agreement

- Industry Registration Certificate

- Duly filled application form of the concerned SPCB

- Balanced sheet by CA

- Copy of CTE

- Proof of pollution control devices with their location, capacity and exit points of the discharge etc.)

- Copy of land-related documents

- Consent fee (as applicable)

- Laboratory analysis report of the trade effluent and emissions

- Any other document specified in the form

Extra Licenses Expected by a Pulse Milling Industry

Aside from the one referenced over, the accompanying licenses are additionally expected by the pulse milling industry –

- Company Registration or Registration of Proprietorship or Partnership Firm

- IEC Code, in case of export of pulses

GST Registration

Market Outline of the Pulse Milling Industry

In India, over 75% of the beats are showcased and consumed as dehulled parts. There are around 7,000 dal handling factories the nation over. The typical limit of each pulse milling industry. is around 10 tons each day. The market for processed beats/dal is primarily homegrown, where 90% of the produce is consumed in the country. The rest is being traded. India traded 410,375.89 MT of heartbeats worth Rs. 2,834.23 crores during 2021-22. This information shows a more critical interest for processed beats in the nation and, thusly, a business opportunity for the new pulse milling industry.

How will Enviroexperts Assist You?

| Customized help for your business arrangement | Start-to-finish direction | Financially savvy answer for all business needs |

| Enviroxperts professionals are capable attorneys CAs and CS who give altered help with setting up Pulse Milling Industry and related legalities like authorizing, authorisation administrations and legitimate guide. | We offer direction in procedural and documentation for processing organizations in any condition of the country. Our group of specialists helps in the arrangement of your business as well as in proactively keeping you refreshed with any progressions in government approaches that can be of worry to you. | Our client connection group gives exhaustive and master help to any questions and inquiries of the client rapidly and productively. |